- Sharples As 26 Centrifuge Manual Download

- Sharples As 26 Centrifuge Manual Instructions

- Sharples Centrifuge P3400 Manual

We are an owner-managed family-run company with short reaction times, constant contact persons and individual service.

The company founder Dipl.-Ing. Stephan Winkelhorst started his career in 1958 as an employee at the Fa. Westfalia Separator and earned comprehensive procedural and machinery knowledge, which he introduced into the company, Winkelhorst Trenntechnik GmbH, after 20 years of practical activity for Westfalia Separator.

Both his sons have taken over the Management, meanwhile; Stephan Winkelhorst still is active in the company.

More about Centrimax

Based on 50 years of experience in the field of centrifugal separation technology, we were able to acquire procedural and machinery know how, with the result to be able to supply our customers compentent counselling that covers all manufacturers.

More about Counselling that covers all manufacturers

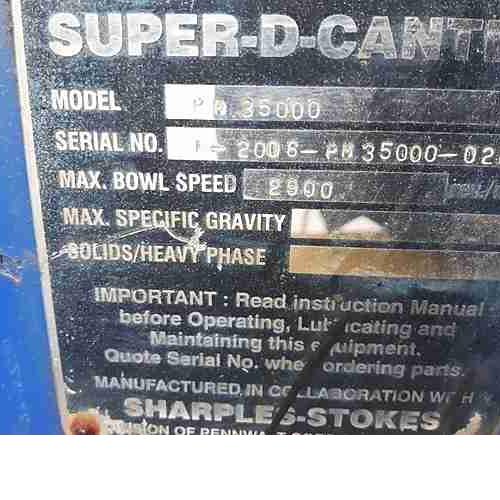

Sharples Centrifuge As 26 Manual AS 26 SHARPLES CENTRIFUGE, S/S - Federal Equipment Reconditioned Sharples P-2000 decanter centrifuge. 14″ x 22″ bowl dimensions. 10 degree beach. 4000 RPM maximum bowl speed. 3180 x G maximum G-force. All stainless steel product contact areas. Available with P-52, 125 or 165: 1 gear. Sharples/Alfa Laval manufacture hi-speed vertical tubular bowl centrifuge units that spin at 15000 RPM. For batch type process, this centrifuge was designed for clarifier, 2 phase liquid/liquid, liquid/solids having very low solids content, or separator, 3 phase liquid/liquid/solids again having very low solids. AS 26 Alfa Laval - Sharples Tubular Centrifuges. Manufacturer: Alfa Laval - Sharples. Description: Tubular Centrifuges. Send us an inquiry for this machine!

The centrifuges, we deliver, go through a complete- or service overhaul, from our side. The overhauls are being carried out and supervised by experienced experts. Before delivery the centrifuges are undergone extensive tests on our own engine test bed. On request the centrifuges are delivered without any overhaul, „as is“.

General overhaul in 12 steps:

The general overhaul covers, in extend to the work steps of service overhaul, a complete disassembly of the machines in order to measure and test more precisely.

More about general overhaul

Service overhaul in 7 steps:

In the context of service overhaul our specialists test the most important machine parts for wear and tear. Bearings and seals are being replaced.

More about service overhaul

Our large stock consists of separators decanters and miscellaneous industrial centrifuges of well known manufacturers as GEA Westfalia Separator, Alfa Laval, Flottweg, Siebtechnik etc. for almost all purposes.

Our stock

Sharples As 26 Centrifuge Manual Download

On purchase of a second hand, but general overhauled centrifuge with warranty of Centrimax you can save up to 70% opposing the cost of a new machine.

Before delivery, we undergo our general-overhauled centrifuges a comprehensive function test on our engine test bed. Only after successful passing all tests, we deliver our machines with a 7 month warranty aboard or 13 month warranty within Germany.

Character of a new machine throughout general overhaul.

In order to receive a durable, dependable and long-life centrifuge, you should buy second hand centrifuges from centrifuge specialists, only.

Subject to centrifugal forces, the denser solid particles are pressed outwards against a rotating bowl wall, while the less dense liquid phase forms a concentric inner layer in a decanter centrifuge. Different dam plates are used to vary the depth of the liquid – the so-called pond – as required. The sediment formed by the solid particles is continuously removed by the screw conveyor, which rotates at a different speed than the bowl. As a result, the solids are gradually “ploughed” out of the pond and up the conical “beach”.

Sharples As 26 Centrifuge Manual Instructions

The centrifugal force compacts the solids and expels the surplus liquid. The dried solids then discharge from the bowl. The clarified liquid phase or phases overflow the dam plates situated at the opposite end of the bowl. Baffles within the centrifuge casing direct the separated phases into the correct flow path and prevent any risk of cross-contamination.

Sharples Centrifuge P3400 Manual

The speed of the screw conveyor may be automatically adjusted by use of the variable frequency drive (VFD) in order to adjust to variation in the solids load.

Comments are closed.